rrr

rrr

rrr  rrr

rrr rrr

rrr

rrr  rrr

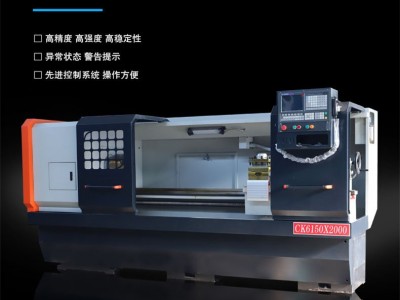

rrr rrr ck6140数控车床产品性能特点:r rr ◆高精度滚动轴承支承主轴,回转精度高rrr ◆全封闭罩壳,安全可靠r rr ◆外形设计美观rrr ◆功能全面、加工效率高、操作简便r rr 产品用途:rrr ◆该机适用于各种钢材,铸铁和有色金属大中型零件的加工,机床功率大,刚性好,特别适用于强力切削,切削各种工件的内圆、外圆,端面,以及公英制螺纹等,并可承担钻孔镗孔等工艺。r r

rr

r rr

r rr | r r 技术参数r r | rr r Specificationsr r | rr r 单位r r | rr r CK6140r r | r

| r r 床身上最大回转直径r r | rr r Max.swing over bedr r | rr r mmr r | rr r Ф400r r | r

| r r 托板上最大回转直径r r | rr r Max.swing over cross slider r | rr r mmr r | rr r Ф180r r | r

| r r 最大加工长度r r | rr r Max.processing lengthr r | rr r mmr r | rr r 750r r | r

| r r 最大行程X/Zr r | rr r X/Z axis travelr r | rr r mmr r | rr r X:220 Z:1050/1600r r | r

| r r 主传动形式r r | rr r Spindle transmission typer r | rr r | r r r 二档机械变速 档内变频无级r r | r

| r r 主轴转速级数r r | rr r Spindle speed steepr r | rr r | r r r 无级r r | r

| r r 主轴转速范围r r | rr r Spindle speedr r | rr r rpmr r | rr r L:70~560,H:200~1600r r | r

| r r 主轴端部形式r r | rr r Spindle noser r | rr r | r r r C6r r | r

| r r 主轴孔直径r r | rr r Thru-hole dia.of spindler r | rr r mmr r | rr r 52r r | r

| r r 主轴孔前端锥度r r | rr r Spindle taperr r | rr r | r r r MT6r r | r

| r r 主轴电机功率r r | rr r Spindle motorr r | rr r KWr r | rr r 5.5r r | r

| r r 卡盘尺寸r r | rr r Chuck sizer r | rr r mmr r | rr r 200r r | r

| r r 滚珠丝杠直径×螺距(X/Z)r r | rr r Ball screw dia.and pitchr r | rr r mmr r | rr r φ25X6/φ40X8r r | r

| r r 进给电机扭矩X/Zr r | rr r X/Z axis feed motor torquer r | rr r N.mr r | rr r X:6 Z:10r r | r

| r r 进给电机功率X/Zr r | rr r X/Z axis feed motor powerr r | rr r KWr r | rr r X:1.5 Z:2.5r r | r

| r r 快移速度X/Zr r | rr r X/Z axis fast moving speedr r | rr r mm/minr r | rr r X:6000 Z:8000r r | r

| r r 定位精度(X/Z)r r | rr r X/Z axis Position accuracyr r | rr r mmr r | rr r 0.02/0.025r r | r

| r r 重复定位精度(X/Z)r r | rr r X/Z axis repeatabilityr r | rr r mmr r | rr r 0.01/0.015r r | r

| r r 工件加工精度r r | rr r Processing accuracyr r | rr r | r r r IT6-IT7r r | r

| r r 工件表面粗糙度r r | rr r Workpiece surface roughnessr r | rr r | r r r Ra1.6r r | r

| r r 尾座套筒直径r r | rr r Tailstock sleeve dia.r r | rr r mmr r | rr r 65r r | r

| r r 尾座套筒行程r r | rr r Tailstock sleeve travelr r | rr r mmr r | rr r 140r r | r

| r r 尾座套筒锥度r r | rr r Tailstock sleeve taperr r | rr r #r r | rr r MT4r r | r

| r r 刀架形式r r | rr r Tool post formr r | rr r | r r r 电动四工位r r | r

| r r 刀具外形尺寸r r | rr r Cutting tool shape sizer r | rr r mmr r | rr r 20x20r r | r

| r r 导轨形式r r | rr r Guide formr r | rr r | r r r 单山 平轨r r | r

| r r 总电源容量r r | rr r Total power capacityr r | rr r KVAr r | rr r 10r r | r

| r r 外形尺寸r r | rr r Machine dimension(L×W×H)r r | rr r mmr r | rr r 2500x1500X1650r r | r

| r r 机床重量r r | rr r N.W.r r | rr r kgr r | rr r 2300r r | r

| r r 本机床已装配完滚珠丝杠、联轴器、装配式主轴、液压站、液压尾座、润滑油路、卡盘、回转油缸及刀塔,电路、电机、电器、电箱、钣金。r r | r|||

| r r 序号r r | rr r 名称及规格r r | rr r 数量r r | rr r 标准配置r r | r

| r r 1r r | rr r 数控系统r r | rr r 1/台r r | rr r 系统可选(广数,台湾,发那科,西门子)等r r | r

| r r 2r r | rr r 卡盘r r | rr r 1/台r r | rr r 三爪卡盘K11 250(选配K11 380)r r | r

| r r 3r r | rr r 尾座r r | rr r 1/台r r | rr r 手动尾座r r | r

| r r 4r r | rr r X向滚珠丝杠r r | rr r 1/台r r | rr r 北方机械/富力康r r | r

| r r 5r r | rr r Z向滚珠丝杠r r | rr r 1/台r r | rr r 北方机械/富力康r r | r

| r r 6r r | rr r 电动刀架r r | rr r 1/台r r | rr r LD4B-A(6150)r r | r

| r r 7r r | rr r X、Z向丝杠轴承r r | rr r 各1套/台r r | rr r 国产r r | r

| r r 8r r | rr r X、Z向联轴器r r | rr r 各1套/台r r | rr r 国产外购r r | r

| r r 9r r | rr r 主 轴 轴 承r r | rr r 1套/台r r | rr r 国产r r | r

| r r 10r r | rr r 机身铸造r r | rr r 1/台r r | rr r 采用树脂砂铸造r r | r

| r r 11r r | rr r 主轴总成r r | rr r 1套/台r r | rr r 装配式主轴r r | r

| r r 12r r | rr r 主轴夹紧方式r r | rr r | r r r 手动卡盘r r | r

| r r 13r r | rr r 油 漆r r | rr r 1套/台r r | rr r 颜色可根据客户要求进行配置,未特殊要求的按我司标准颜色配置r r | r

| r r r r | r r | rr | rr r 合资沪润(电动润滑油泵,润滑油路安装完毕)r r r r r r r r | r

r

r