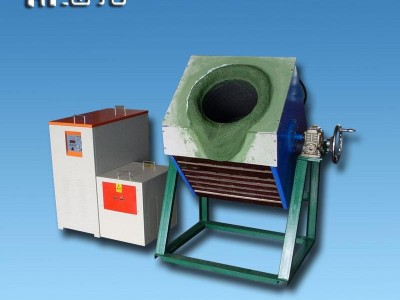

中频碳化炉 Middle frequency carbide furnace 一、应用 used in l 硬质合金、粉末合金行业生产各种颗粒的碳化钨、碳化钛、碳化钒等金属粉末,复合金属粉末, 烧结合金及钨钼制品等。 Hard alloy powder alloy industry, production of various granular tungsten carbide, titanium carbide, vanadium carbide, me

tal powder, me

tal powder sintered alloy and composite, such as tungsten and molybdenum products. 二、性能简介 Function l 2400℃不锈钢超高温水冷炉体. 2400℃ super-high temperature stainless steel furnace body with water cooling . l 可满足细 中 粗颗粒碳化钨粉和复合料碳化加热工艺,也可用于合金料烧结。 Meet heating technology of thin, middle, coarse particles and compound material carbonization. It is also used in alloy material sintering. l 全新的工作情况监视系统,适时监控设备运行情况,具备故障自诊断功能; Supervising system for the working and device with trouble self-diagnosis. l 采用数显智能化控温系统,全自动高精度完成测温控温过程,系统可按设定升温曲线升温,并储存二十组, 每组二十部不同加热曲线,或人工控制; Adopt number display intelligent control temperature system, Finish temperature measure and control with auto high precise, It can raise temperature according to the setting raising temperature curve, and storage 20 groups, 20 different heating curve for each group. Or It can be controlled by manual work. l 采用纯水循环处理系统:数字式流量监控系统,高性能中频接触器,PLC自动控制系统,CPU自动检测水流量。 Adopt pure water cycle processing system: Number-supervising system for the rate of flow, middle frequency contact device with high function, auto-control system with PLC, automatic detection discharge of water with CPU. l 该新型碳化炉对碳化质量有明显改善,与传统碳化炉相比,具有反应完全,粒度均匀,化合含碳量高, 游离含碳量低等优势,而且有产量高,劳动条件好,使用寿命长等特点: The carbonized quality has the distinct improvement with this new furnace, compares with the traditional carbide furnace, it has the superiority with the complete response, the even granularity, the high chemical combination carbon amount, low dissociation carbon amount and has the characteristics with the high output, the good work condition, life long. l 控制按钮少,功能全,控制面板操作简单;可配置触摸屏,人机界面系统。 The control push-button is few, function is entire, the operation of control panel is simple, You can install the touch-screen to realize the man-machine surface system. 三、技术参数technique parameters

额定功率

| 额定频率

| **高使用温度

| 高温区容积

| 炉内工作气氛

| 温度均匀值

| 测温范围

| 温度测量

| 控温精度

| 极限升温速度 |

| 160KW 200KW 250KW | 4000Hz | 1600℃ 2400℃ | ¢450×900mm | 氢气、氮气、氩气、惰性气体等 | <±12℃ | 200-2200℃、800-2400℃ | 红外线光学测量 | ±1℃ | 400℃/min |

其他规格可按工艺要求定制。Making for you according to your request. 质量保证,欢迎致电详询!杨经理 13873301595